Hydraulic Cylinder Repair Near Me

Hydraulic Repair | Hydraulic Motor Repair | Hydraulic Cylinder Repair

Hydraulic Cylinder Repair Near Me

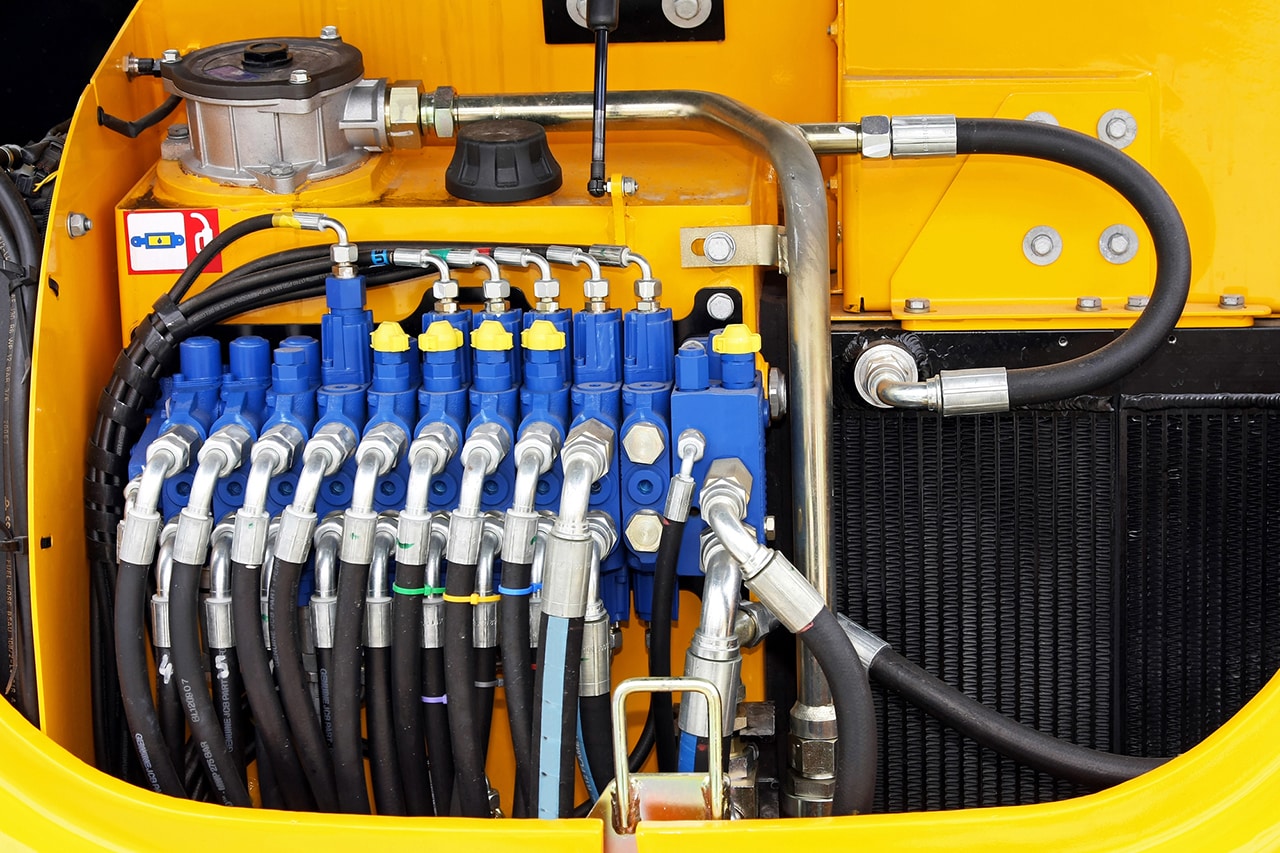

There are various types of cylinders, and the repair process depends on which style is involved. The most common cylinder types are either wire ring or threaded head. During the repair process, all components should be rinsed in a petroleum-based solvent, blown dry via compressed air, and coated with hydraulic fluid before installation.

When checking the components for damage, it is essential not just to address the damage (i.e., resurfacing or polishing) or replace the parts involved but troubleshoot why the damage happened in the first place. If a repair is done without finding out what caused the problem in the first place, given sufficient time, the repair will have to be repeated. Hydraulics experts like us at 1928 Hydraulic Repair can recognize the signs of common issues and see that the source of the matter is addressed and the necessary repairs being done.

The hydraulic cylinder repair process involves attention to detail and comprehensive visual inspection — both of which often require many years of experience to master. Most repairs, such as fabricating rods and honing tubes, are best done by professionals.

Here at 1928 Hydraulics, hydraulic cylinder repair is one of the services that we provide. We can install new seals, polish rods, hone tubes, and manufacture replacement components for your hydraulic cylinders, no matter the brand. Our state-of-the-art facilities support rod, tube, and cylinder fabrication as well as welding and machining. If your hydraulic cylinders require repair, call 1928 Hydraulic Repair today for efficient, quick, high-quality service.

San Antonio Hydraulic Cylinder Repair

Hydraulic cylinders can be seen in almost every industry, ranging from the clean, sterile food and beverage environment to the rugged and rough world of construction. When these cylinders drop in performance or outright fail, the word “replace” comes to mind. Replacing a cylinder may look like a great option to avoid the failure from occurring again. Still, the cost to replace a cylinder is no insignificant amount. When the time comes to make that decision, should you replace a damaged cylinder or choose a repair instead?

There are several benefits to repairing a hydraulic cylinder. In most failure instances, a specific component fails instead of the entire system, leaving other parts in outstanding condition as long as the failure is discovered and fixed relatively quickly. Only the damaged part has to be replaced in such cases, as is familiar with seal and bearing problems. Also, repairs may be more economical than replacements and, with customized cylinders, may involve far less lead period.

Hydraulic cylinders are crucial to keeping things moving, figuratively and literally. When issues occur, and failures arise, there comes a time when you have to choose whether to repair the cylinder or get it replaced. A significant amount of information has to go into that decision, ranging from the cylinder’s expected lifespan to the lead time involved in a replacement. Cost issues are affecting the short-term economic benefits and the repairs or replacement cost over the long term. The key to such decisions is why failure occurs in the first place: was the cylinder simply worn out, or are there any underlying issues (e.g., alignment, hydraulic contamination) that have to be addressed before a solution is set into place?

Here at 1928 Hydraulic Repair, we focus on San Antonio Hydraulic Cylinder Repair. You can rely on our team to track down the root cause of the failure and make suggestions so you can prevent it from happening again. Call us today to learn what we have to offer in hydraulic cylinder repair. Learn more about Hydraulic Repair.

Hydraulic Cylinder Repair Companies

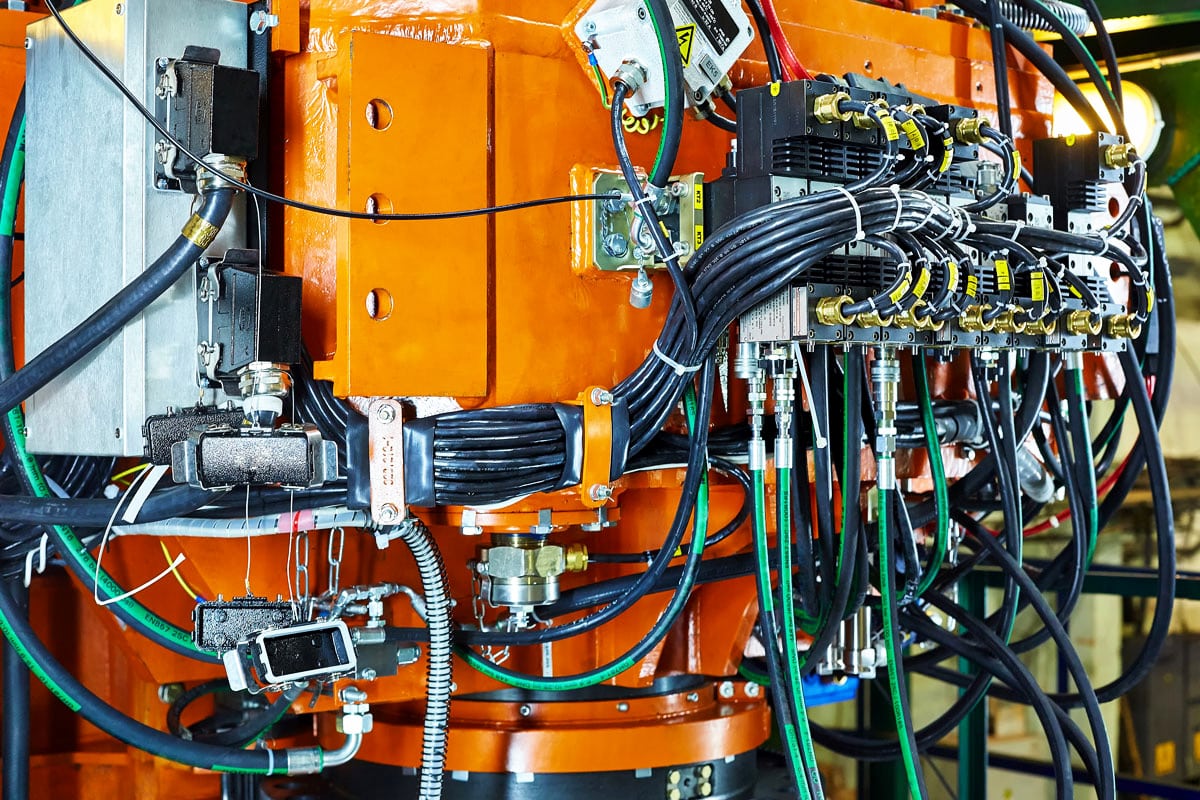

Hydraulic cylinders are systems that utilize the pressure of a liquid to conduct mechanical work. They allow tools and machines to develop significant output forces using the principles of hydraulic and pressure. Hydraulic cylinders are commonly used in construction equipment, vehicles, manufacturing machinery, and hydraulically powered tools. These cylinders function by transferring liquid from one fraction of an enclosed system to another, applying an output pressure. This pressure works on a piston on the other side of the system, forcing it upward to hoist a particular load. Hydraulic cylinders are valuable since a minor force applied at a considerable distance can be transformed into a large force that maneuvers at a shorter distance.

Hydraulic cylinders, such as with any other machinery with moving parts, are susceptible to failure and wear. These sophisticated chunks of equipment require all parts and components to work together in unison. The entire system performance can be influenced if even the tiniest detail is compromised. Therefore, it is essential to conduct regular hydraulic cylinder testing, inspection, repair, and maintenance to guarantee these systems work at optimal capacity.

We know what it takes to do everything from quick, standard cylinder repairs to turnkey projects with maintenance downtimes.

Repairing hydraulic cylinders is indeed a very complex process that needs the right tools and the right hydraulic cylinder repair companies. 1928 Hydraulic Repair‘s extensive capabilities enable us to effectively improve several hydraulic cylinders and recommend mechanical and structural improvements. Our services provide our customers with a one-stop solution for all their hydraulic needs, from troubleshooting and testing to installation and repair. To book a hydraulic cylinder repair service, call us today!

Hydraulic Cylinder Repairs

Faulty hydraulic cylinders cause downtime. That’s lost time and money that you and those who rely on you can’t afford. When you need hydraulic cylinder repairs, it makes sense to depend on a company with a track record of reliable service, high-quality maintenance, and practical solutions. That’s precisely what we at 1928 Hydraulic Repair deliver: reliable, rigorously-tested hydraulic repair, hydraulic pump repair, and more that end downtime and get your production processes back to optimum efficiency.

From the time you contact 1928 Hydraulic Repair for hydraulic cylinder repair services, we commit our efforts to ensure that you get your parts back in outstanding working condition. The outcome is a cylinder that meets or exceeds OEM specifications and is operated according to its initial pressure rating.

1928 Hydraulic Repair is your best choice for fast, reliable, professional hydraulic cylinder repair services when a hydraulic cylinder breaks down. Working with 1928 Hydraulic Repair’s hydraulic repair team provides you with access to a wealth of experience in root-cause analysis, troubleshooting, and hydraulic system design acquired over years of experience in repairing, remanufacturing, and upgrading hydraulic systems. That’s why our customers trust our hydraulic systems repair experts to keep their equipment functioning at peak performance.

As specialists in hydraulic cylinder repair, we excel at locating the causes of hydraulic cylinder damage and performing long-lasting maintenance. To prevent long-term system failure, our crew will work with you to formulate a maintenance plan that matches your schedule and reduces the risk of future unexpected shutdowns.

Here at 1928 Hydraulic Repair, we believe in building lasting relationships with our clients the old-fashioned way by providing real value through quick, professional service and honest, straightforward communication. When you call us, visit our shop, or welcome our mobile service crew into your facility, you’ll meet a devoted person to solving your hydraulic problems.