1928 Hydraulic Repair

Hydraulic Repair | Hydraulic Motor Repair | Hydraulic Cylinder Repair

Hydraulic Repair Services

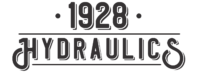

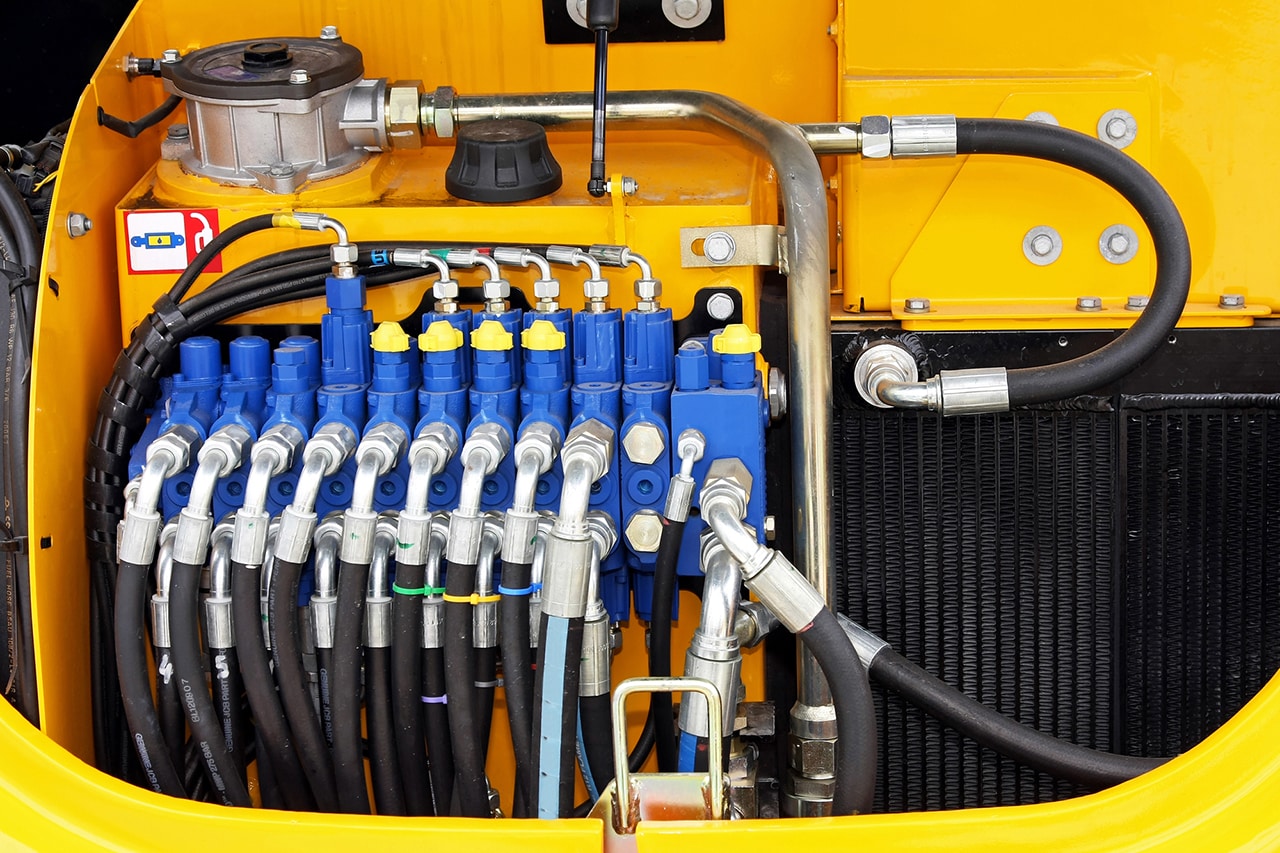

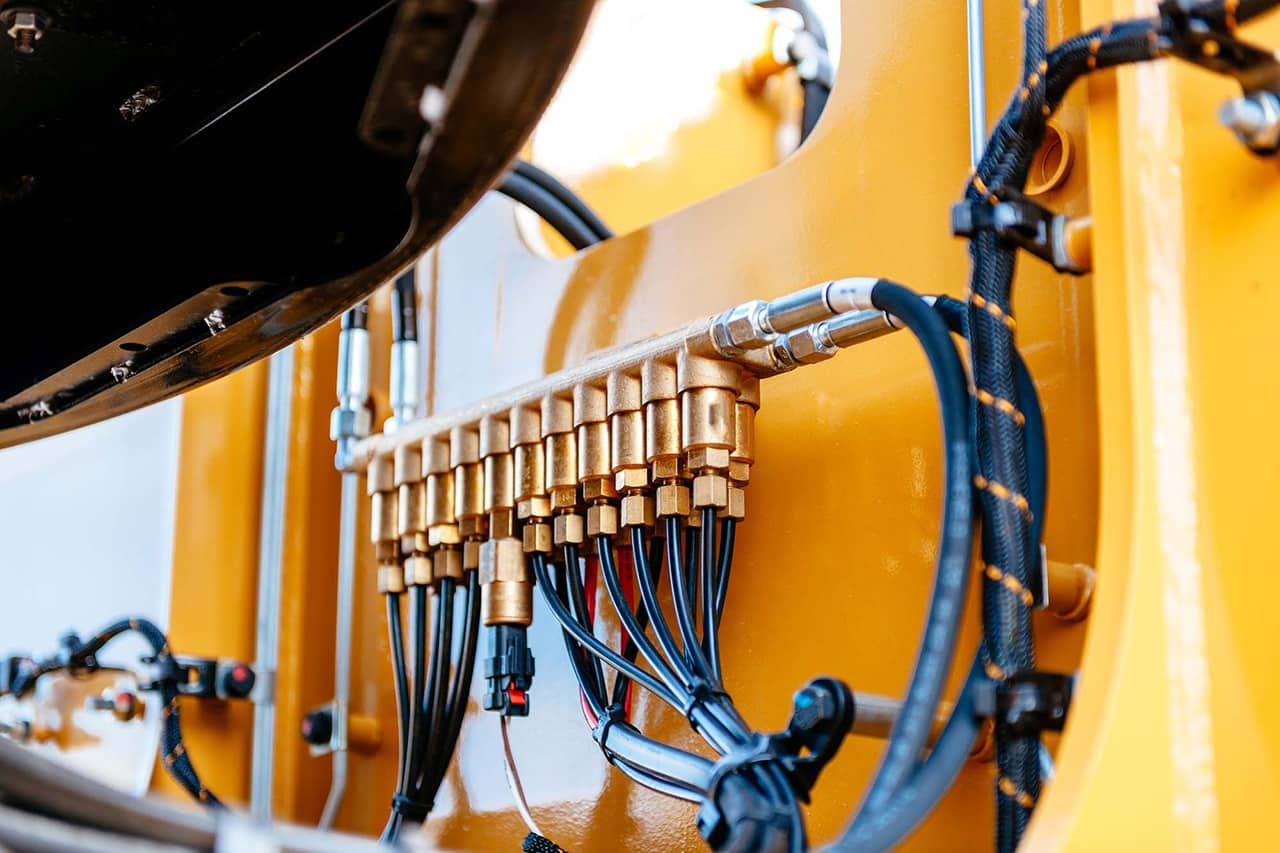

Heavy construction equipment operates on powerful hydraulics. Hydraulic systems include pumps, motors, hoses, cylinders, and valves. These and other hydraulic parts require regular maintenance to keep performing at exceptional levels.

1928 Hydraulic Repair is a full-service hydraulic repair and maintenance provider. We work with customers in agriculture, landscaping, construction, and other industries. With areas throughout San Antonio, Texas, we can provide both shop and field service for all hydraulic equipment.

Hydraulic equipment is complicated, and the machines that count on it are often expected to operate in demanding conditions. There are several aspects to keeping these systems working their best:

Preventive maintenance: This is the best investment you can make for hydraulic components. Regular checkups allow our team to watch for signs of damage that can cause a problem later.

Repairs: Leaks are the most frequent hydraulic service issue. Options for handling them include cylinder resealing and honing, straightening, and retubing. Fixing a hydraulic cylinder is the most cost-effective way to address minor problems.

Remanufacturing involves:

- Taking apart a cylinder.

- Replacing all wearable items.

- Conducting a series of tests to take it back to factory specs.

Remanufacturing can extend years of life to a hydraulic cylinder at a fraction of the replacement cost.

Replacement: Replacing a hydraulic cylinder is an alternative for severely worn components. 1928 Hydraulic Repair delivers hydraulic replacements using new OEM, aftermarket, and reconditioned parts.

What are the advantages of quality hydraulic services?

- You’ll be able to locate problems ahead of time and schedule repairs subsequently.

- You’ll have the peace of mind of knowing your equipment is running its best

- You’ll save the hassle and expense of an emergency repair

- You’ll avoid downtime that can disrupt your productivity

1928 Hydraulic Repair offers hydraulic service as part of our extensive equipment management services. We can evaluate your fleet and arrange a schedule that meets the manufacturers’ suggestions.

Learn more about Hydraulic Repair Services.

Hydraulic Hose Repair Near Me

Most heavy equipment depends on hydraulics for almost every facet of its operation. A hydraulic system needs the efficient transmission of fluid to allow a machine and its components to run and perform work. Hoses are essential for providing a flexible connection between two ports to promote efficient, unobstructed fluid flow.

Hydraulic hoses are crucial to a machine’s ability to operate correctly. And as you know, when a hose breaks, it means costly downtime that puts your projects behind schedule. Getting access to an experienced service provider is vital to replace broken hoses quickly and get your equipment back on the job.

1928 Hydraulic Repair can do hydraulic hose repair work on nearly every hydraulic hose brand there is. Our fully equipped repair shop features the latest tools and technology to perform the task quickly and efficiently, whatever make or model.

We also possess the best experts in the region. Our team can troubleshoot and develop the hydraulic hose you need with a while-you-wait service. Also, our parts inventory carries a wide selection of hoses, adapters, and fittings.

Services you can expect:

- Load & pressure testing

- Install & supply low, medium & high-pressure hoses with either reusable or permanent crimp couplings.

- Repair & replacement for all hose sizes

- Foam core plug cleaning & ends capped to block contaminants

- Fluid analysis & other diagnostics for hydraulic systems

With our years of experience and expertise, you’ll gain confidence knowing that the job is done precisely and that your hose rebuild or repair will meet your expectations and alleviate any performance or reliability concerns.

Learn more about Hydraulic Hose Repair Near Me.

Hydraulic Hose Repair

When you are running an industry, spending the day at the hydraulic hose repair shop is the last thing your team wants. Here at 1928 Hydraulic Repair, we excel in hydraulic hose repair. If you need reliable repair services for your hydraulic hoses, you can get them from us in record time and at a competitive price.

Our crew prides itself on getting you the parts you need to get back to your job site as soon as possible.

We believe that our components are the most durable solutions available. That quality means you get the benefit of speed and high performance.

Lessen your downtime with hydraulic hose repair from us at 1928 Hydraulic Repair. We extend a range of replacement and solutions options and are committed to providing the right level of service and advice to satisfy your needs. 1928 Hydraulic Repair has the equipment and expertise to make almost any hose assembly you’ll need – on the spot.

1928 Hydraulic Repair offers multi-channel service solutions to satisfy every customer’s need for speed. Do-it-Yourself servicing is quick, and we also ensure swift support from our field technicians and in-store with our expert staff.

Here at 1928 Hydraulic Repair, you are always in safe hands. We’ll arrive at your property using the latest tools, routing standards, inspection techniques, assembly information, and contamination control processes to have every machine up and running reliably and in no time. The result? Reduced downtime and more productivity for all machines. Call us today!

Learn more about Hydraulic Hose Repair.

Hydraulic Cylinder Repair Near Me

Hydraulic cylinders are systems that utilize the pressure of a liquid to conduct mechanical work. They allow tools and machines to produce superior output forces using the principles of hydraulics and pressure.

Hydraulic cylinders are usually used in vehicles, manufacturing machinery, construction equipment, and hydraulically powered tools. These cylinders work by carrying liquid from one part of an enclosed system to another, applying an output pressure. This pressure works on a piston on the other side of the system, pushing it upward to lift a particular load. Hydraulic cylinders are essential since a small force applied at a large distance can be turned into a large force that travels at a shorter distance.

Hydraulic cylinders, such as with any other machinery with moving parts, are prone to wear and tear. These sophisticated pieces of equipment need all parts and components to work together in harmony. The entire system performance can be influenced if even the smallest component is compromised. Hence, it is essential to perform regular hydraulic cylinder inspection, testing, and maintenance to ensure these systems work at optimal capacity.

Here at 1928 Hydraulic Repair, we concentrate on hydraulic cylinder repair, reconditioning, overhaul, and testing. We thoroughly analyze and evaluate every aspect of the cylinder using our state-of-the-art equipment, testing methods, and simulation software. We identify all possible defects and modes of failure with our thorough diagnostics and hydraulic cylinder inspection techniques and conduct the appropriate maintenance or repair procedure. With years of experience, combined with our cutting-edge tools and services, allow us to repair hydraulic cylinders with greater efficiency, translating to superior cylinder reliability and performance.

Hydraulic cylinders are available in numerous unique sizes and configurations depending on their purpose. Our vast range of industry-leading hydraulic cylinder repair can satisfy the needs of many industries, including automotive, transportation, and construction. We also thoroughly check all our repairs to ensure they meet every specification.

Fixing hydraulic cylinders is a complex process that needs qualified technical experts and the right tools. Our extensive capabilities allow us to effectively improve many hydraulic cylinders and recommend structural and mechanical improvements. Our offerings provide our customers with a one-stop solution for all their hydraulic needs, from troubleshooting and testing to repair and installation. To schedule a hydraulic cylinder repair service, contact our team of technical experts today.

Learn more about Hydraulic Cylinder Repair Near Me.

Hydraulic Repair

Whether working in industrial, automotive, or railroad environments, companies across various industries depend on hydraulic pumps, motors, cylinders, and valves. Hydraulic pumps provide ten times more power than electric motors at a comparable volume. Meanwhile, flexible hoses and compact hydraulic tubes generate incredibly high-power density for several applications in a safe and simple operation.

We at 1928 Hydraulic Repair team has been engineering, maintaining, and repairing parts for hydraulic equipment. Backed up by years of experience, we understand the significance of quality repair and components. Whether handling production automation or custom lubrication systems, we tailor our hydraulic repair services to match your specific needs.

Professional Hydraulic Maintenance & Repair

For custom systems, comprehensive cylinder examination and diagnosis will enable an efficient, effective repair solution – at a faster turnaround and significantly lower cost than replacement. Honing, resealing, rebuilding, and even simple hose replacement can give new life to an aging hydraulic system.

A standard piece of hydraulic-powered machinery or heavy equipment may have thousands of individual, sealed connection points – all of which are susceptible to leaks. If your hydraulic jack system leaks, fails to create its required output or produces a sudden excess of noise, heat, or vibration, it could be due for a life-lengthening inspection and repair.

Here at 1928 Hydraulic Repair, we specialize in hydraulic repair services and can even fabricate replacement hoses in various pressure, temperature, and fluid compatibility grades while you stand by. We’re proud to provide all our customers a vast inventory of new equipment, service parts, and custom fabrication options. Call us today!

Learn more about Hydraulic Repair.

Mobile Hydraulic Repair

We at 1928 Hydraulic Repair provide leading mobile hydraulic repair services across San Antonio, Texas, with our fully equipped fleet of mobile recovery workshops with the equipment to assemble hydraulic hoses on-site. We take pride in quick and efficient response to your hydraulic emergency.

Here at 1928 Hydraulic Repair, we know the impact that an on-site breakdown can have on your business; that’s why we will always handle every job with fundamental values such as honesty, reliability, and excellent levels of customer service.

Our main aim is to essentially ensure that your machinery gets back up and running as soon as possible. In addition, we ensure that we provide the best solution by using our expert knowledge and highly-skilled engineers that can handle all types of repairs.

Our experts will perform all repairs by meeting industry standards and have a complete success rate in handling breakdowns and repairs on-site.

With our crew of highly skilled engineers on hand, we can present you with leading-edge on-site hydraulic hose repairs. Our standards are fixed to a premium to guarantee that you will always get nothing short of outstanding services from us at 1928 Hydraulic Repair.

We can give you an on-site hose repair service, and our qualified technicians can also provide a diverse flow of knowledge to get you the ultimate peace of mind about using our services for any of your on-site hydraulic breakdowns and repairs. Call us today!

Learn more about Mobile Hydraulic Repair.

Mobile Hydraulic Hose Repair

We 1928 Hydraulic Repair offer excellent mobile hydraulic hose repair services. Rather than bringing your hoses to a workshop for repairs, we take the workshop to you. Our vans are equipped with hoses and fittings for a vast range of applications, including guards and clamps. The specialist we assign to the job will have a thorough understanding of hydraulic breakdowns and related systems.

This means that we’ll constantly leave enough slack to keep the system operational, but with measures set into place that stop instances of impending damage. We carry out hydraulic hose repairs in San Antonio, Texas.

Loss of system performance and visible leaks point towards an issue with the hoses. Our technician will execute a prompt decision on whether those hoses require repairing or replacing. Usually, the final decision lies with how we can best minimize disruption. 1928 Hydraulic Repair works tidily and cleanly to reduce oil contamination and keep workplaces safe for system users and other employees.

Hoses move fluids to different parts of a hydraulic system. These hoses, mostly made from steel-reinforced rubber or steel tubes, work under extreme pressures. When they begin to leak, you could experience poor system performance at your San Antonio, Texas premises, or in a worst-case scenario, it could cause a complete breakdown. Bear in mind that hydraulic hoses only have a finite lifespan.

Failure could cause injury, so if you notice an issue, arrange to have us conduct a hydraulic hose repair or replacement. We offer a genuine emergency mobile service.

Brittle or frayed hoses can result in a hydraulic breakdown, so it pays to have them regularly inspected. This is a basic form of preventative maintenance and will usually help identify problematic hoses before they bring your machinery, plant, or systems to a complete standstill.

Age, poor assembly, incorrect insertion, overheating, tight bends, and the use of incompatible fluids can all result in a hydraulic hose failing. We not only replace and repair hoses, but we can also advise on how to prevent recurring problems.

Here at 1928 Hydraulic Repair, we understand that downtimes and breakdowns are not options for you or your business. We respond to calls from clients in San Antonio, Texas. Our main objective is to have your hoses repaired or replaced fast and have your plant or machinery back up and running.

A responsive hydraulic hose repair service can stop your company from losing time, money, and productivity. Call us today!

Learn more about Hydraulic Hose Repair.

Hose Repair Near Me

Hoses are a fundamental part of any hydraulic component, and often they’re the first to go when wear occurs over time. Luckily for businesses, 1928 Hydraulic Repair offers quick and reliable hydraulic hose repair, replacement, and other services. You’ll discover we have a broad selection of hoses and couplings in stock and can instantly turn around any job.

We are aware of how crucial it is for our customers to receive fast, quality service when their hydraulic hoses fail and their operations had to stop. Call us now to discover more about your service choices.

1928 Hydraulic Repair, going the extra mile for our customers isn’t just an idle promise. We stand behind our words and promises, particularly towards the businesses that keep our economy going.

At 1928 Hydraulic Repair, we have a vast stock of low-, medium- and high-pressure hoses and fittings available to install on your heavy equipment.

1928 Hydraulic Repair has provided repair and maintenance service that meets the exceptionally high standards businesses demand. Choose us for:

Reliable service: We get the task done right the first time by following official guidelines for hydraulic hose replacement.

High-quality results: We thoroughly test every repair to guarantee it delivers the performance and reliability you require.

High-quality parts — We use only premium, genuine parts manufactured from quality materials that provide higher temperature limits and lower lining swell than aftermarket options.

Contamination-free repairs — We accomplish all repairs in a clean environment to eliminate the risk of contamination.

Call or visit today to ask for a free quote.

Learn more about Hose Repair Near Me.

Hydraulic Pump Repair Near Me

When new clients ask what services we can deliver, we keep it honest and reply: “If it’s hydraulic, we can produce it, supply it, solve it or fix it….” That indicates that if you’re searching for a ‘hydraulic pump repair near me’, then your search is over!

As with other hydraulic tools, plenty of our well-repaired and refurbished hydraulic pumps are virtually indistinguishable from a new unit. Our service covers a free evaluation – having checked your existing pump to diagnose the extent of work required and ability to recover and re-use current components.

When assessing your hydraulic pump, our crew could offer advice to enhance its design and productivity so that you could reduce running fees and minimize the probability of any future downtime and hydraulic pump repair work. Our assessment may decide that a hydraulic pump repair is not possible, not good value for money, or simply not advised. If this is the issue, we will quote a new replacement unit and quote for your hydraulic pump repair if suitable.

Nonetheless, repair often signifies a more cost-effective solution than investment in new equipment in the current environment. Here are some well-known signs your hydraulic pump may need fixing or replacing.

Loud noises – Hearing loads of noises from hydraulic pumps is a sign that something isn’t right. Hydraulic pumps are filled with fluids that flow through the system at high speeds and pressures; this can produce a lot of noise which is a clear sign it demands repairing or replacing. That is enough to create a lot of noise; however, hydraulic pumps are designed to muffle such sounds.

Inside Leaks – When you see liquids anywhere inside your pump, other than in the tubes they belong to, there is a defect with the pump. Something as small as a loose seal or valve can result in more severe cases where there is a break in the line. This will create a drop in pressure and malfunction of the whole system. Distinguishing this problem can be a bit trickier because the leak happens on the inside of the pump, but if you thoroughly examine your pump before a long trip, you can locate the problem before it worsens.

Outside Leaks – If you spot liquid outside your hydraulic pump, then the leaking has spread, and action must be taken instantly; this is also a sign the pump is on its last legs. Whether it can be fixed or replaced is best left to professionals such as 1928 Hydraulic Repair. Leaking decreases the pressure and increases the system’s temperature, affecting the oil’s viscosity and further reducing the system’s pressure.

High Working Temperatures – For hydraulic pumps to perform properly, it’s essential to maintain a specific level of fluid viscosity, which banks on the temperature and pressure. If either of these parameters is off, the pump will experience unwanted strain resulting in premature failure.

Temperatures over 82°C (180°F) have a detrimental effect on performance and should be avoided. These temperatures are often reached if the system isn’t cooled properly. Ensure there isn’t any obstruction in the air around the system’s reservoir and check the heat exchanger.

So back to that hydraulic pump repair you were searching for. If you’ve read this far then, you’re hopefully intrigued to give us a try. So what are you waiting for? We guarantee you, your hydraulic unit is in safe hands. Call us now and let us know how we can assist.

Learn more about Hydraulic Pump Repair Near Me.

Mobile Hose Repair

Your company’s success relies on your ability to provide high-quality, uninterrupted service to your customers. Whether your business concentrates on refrigeration devices, irrigation machines, or construction material, you cannot afford to let a defective hose hinder productivity and service. Using mobile hose repair services, you can guarantee that industrial hose defects are addressed as promptly and professionally as possible. Underneath are ten reasons to use 1928 Hydraulic Repair’s industrial hose mobile repair services:

You do not have to halt operations to focus on repairs.

One of 1928 Hydraulic Repair’s top objectives is to allow you to resume production as soon as possible after discovering a broken hose. When you utilize our mobile repair services, the only time you consume on the repair process is the small amount of time you take to call us and request our mobile services. There is no need to halt production and leave your worksite for hours to have your hoses fixed.

Experienced technicians provide service.

Industry experience is just as crucial as prompt service when addressing industrial hose repairs. 1928 Hydraulic Repair’s mobile technicians are prepared to assist clients in various industries such as construction, agriculture, snow removal, and ventilation. They have the skill to address both the complicated and straightforward repair problems that arise with spiral hoses and braided hoses. Finally, our mobile technicians are trained to give the highest customer service and professional level to customers.

You will enjoy a remarkable level of customer service.

Integrity, honesty, and professionalism are the hallmarks of our mobile hose repair service technicians. In addition to timely service and fair pricing, you will enjoy peace of mind knowing that your hoses are improved with high-quality parts. Most importantly, when you get a visit from one of our mobile repair service technicians, you will feel the satisfaction of working with a small local company dedicated to delivering the greatest level of service.

The Bottom Line

Our mobile hose repair service assures that customers receive the prompt, thorough service they want when defective industrial hoses threaten to stop productivity or profitability. With an excellent, strategically placed fleet of mobile repair vehicles, we work hard to provide on-site hose repair service to customers in San Antonio, Texas. Please call us to know how we have become a leader in the industrial hose repair industry.

We look forward to becoming your reliable solution for hose repair!

Learn more about Mobile Hose Repair.

Hydraulic Pump Repair

Hydraulic pumps power most dynamic machines. In hydraulic systems, hydraulic pumps are responsible for pushing fluids of different quantities through hydraulic motors, also called cylinders. The pump is accountable for converting the speed or torque drive’s mechanical energy or force into hydrostatic power in the form of pressure or fluid flow. Hydraulic pumps allow machines with hydraulic systems to perform different tasks such as opening, lifting, rotating, lowering, or even closing components.

The operation of hydraulic pumps is dependent on the displacement principle. As such, hydraulic pumps feature chambers sealed through mechanical procedures. These chambers help the fluid flow from the suction port inlet to the pressure port outlet. The chambers guarantee that the two pump ports have no direct links. Therefore, hydraulic pumps are employed in high-pressure environments such as hydraulics.

Hydraulic pumps are manufactured for varying uses in hydraulic systems with different requirements such as allowed pressure range, medium of operation, drive type, etc. This means that there’s no single pump that can meet all hydraulic needs in its entirety.

Hydraulic Pump Repair Process

Since hydraulic pumps are critical parts of hydraulic systems, their failure can impair the functioning of your systems and machinery. They can be disassembled and rebuilt during the repair. First, the pumps are scrutinized part by part during an examination to uncover the exact problem. Option for repair is then chosen accordingly. Our hydraulic repair procedures usually involve disassembly, problem diagnosis, repair or replacement of failed components, and rebuilding.

Why Our Hydraulic Pump Repair Services are Trusted

Each of our repairs is tested to ascertain they meet factory specifications and industry standards before we leave a job. We have over six decades of combined knowledge and experience serving on production line machinery and hydraulic systems; this has gained us a good reputation as a reliable company.

What Makes Our Hydraulic Pump Repair Services Unique

Our repair service for hydraulics is unique from the competition because we provide full service, including testing, troubleshooting, and repair installation. We also sell parts in-house, so we’re truly a one-stop shop for all your hydraulic and general industry machine needs.

Learn more about Hydraulic Pump Repair.

Hydraulic Repair Shop

Selecting the right hydraulic equipment is key to guaranteeing that your entire hydraulic system operates efficiently and flawlessly.

A quality hydraulic hose will operate to transfer hydraulic fluids (such as oil) effectively from one part of your machine to another. A rupture in the hose could lead to leakage, making your whole hydraulic system completely inefficient. Not only could this become harmful, but your equipment could lose hydraulic power – leaving you with little choice but to invest in expensive and time-consuming repairs.

If you find yourself needing hydraulic hose repair or hydraulic cylinder repair, it’s never a good idea to wait too long before you see a hydraulic repair company.

If you’re looking for ‘hydraulic companies near me on Google, there are several things to remember to guarantee you get the best outcome for your hydraulic repairs. To help you with your search for the best hydraulic servicing company, watch for the following features when you’re looking at options:

Level of Training and Experience

As obvious as this sounds, this is the essential quality that should dictate your decision for the hydraulic repair company you choose to go for. A company with years of experience in hydraulic engineering will have diagnosed and resolved many issues. They are likely to understand what exactly has to be repaired and serviced once they check your systems. The more experienced a hydraulic engineer is, the more likely it is that they’ll be able to locate any problem with your specific system.

When it comes to qualifications, you want to pick a company where the hydraulics engineers have been trained to handle these systems. At 1928 Hydraulic Repair, our group of hydraulic experts has the training and expertise to deliver an extremely high standard of workmanship. You can meet our team of specialists and find out more about their experience online.

Service Offerings

When you want to find replacement parts for your hydraulics system, you want to opt for a company that has a wide range of hoses, pumps, pipes, and cylinders so you can discover the perfect match for your equipment. If the company doesn’t have a wide enough range of products for you, you may be able to get them to build what you need specifically.

It’s also essential to find a company that only offers genuine parts. Unfortunately, many hydraulic parts suppliers are selling counterfeit products. Accidentally getting one of these installed could cause total breakdown and failure of your hydraulic system. Research the manufacturers to ensure they are well-known and high quality. You would want to opt for installations that come with a warranty in case of breakdown within the initial period of use.

Your Convenience is Important

Many hydraulic repair companies can now offer a more flexible service; this is an important quality you’ll need to find when carrying your initial search. You’ll prefer to opt for a company that can furnish you with repair services at any time.

You need to have peace of mind that you’re working with hydraulic engineers to offer you emergency aid whenever you want it. Location-wise, letting your hydraulic repairs and replacements done on your site can considerably speed up the entire process; this means less downtime, and your system will be back up and running before you know it.

If you’re searching for hydraulic hose repairs or fitting specialists in San Antonio, Texas, we at 1928 Hydraulic Repair have the experience to diagnose and resolve any faults quickly. We can take on any repairs within a matter of days. Our squad of hydraulic experts will dismantle and examine the damage to your hydraulics and suggest the best option; this could involve repairs or replacements, which we can custom design to meet your specifications. Call us today!

Learn more about Hydraulic Repair Shop.

Hydraulic Cylinder Repair

Hydraulic cylinders play a crucial role in a wide range of equipment. If they fail, they can result in huge revenue loss for companies as employees and equipment await replacement and repair operations. By working with an experienced and knowledgeable repair service provider, you can guarantee your hydraulic cylinders are brought back to proper working conditions quickly, allowing you to avoid extended equipment downtime and, consequently, substantial profit loss.

Here at 1928 Hydraulic Repair, we offer hydraulic cylinder repair services for various industrial equipment and vehicles. Our highly trained team carefully disassembles, checks, evaluates, repairs, reassembles and tests hydraulic cylinders to get them back to working conditions. If a broken component is irreparable, we can reverse engineer the part to build an appropriate replacement.

Primary Causes for Hydraulic Cylinder Failure

Several signs of a hydraulic cylinder may soon indicate that you need hydraulic cylinder repair or replacement, such as leaking hydraulic fluid or damaged components (e.g., barrel, piston, or mounting). Nevertheless, hydraulic cylinders can also fail without notice. By identifying and understanding the causes of failure and, if applicable, their warning signs, you can see for them and execute an appropriate solution before failure happens.

Some of the most usual reasons for hydraulic cylinder failure are:

Contaminated fluid. The presence of foreign substances in the hydraulic fluid may damage the cylinder by scoring and scratching the interior surfaces or chemically degrading the internal components.

Physical strain. Physical strain, aside from contaminated fluids, can damage the hydraulic seal, influencing the component’s ability to regulate internal pressures and operate efficiently and effectively.

Sideloading. Sideloading is the application of force perpendicular to the hydraulic cylinder’s axis of movement. It can strain various components (e.g., rod bearings or piston rods), which can create damage and, over time, failure.

Intense pressures/temperatures. Hydraulic cylinders are designed for use at certain internal pressures. Pressure levels that stray from this acceptable range can negatively impact the cylinder’s performance. Likewise, the materials used for hydraulic cylinders are picked for specific temperature ranges. Exposing a cylinder to temperatures over or below this range can cause damage to its parts.

Our experts at 1928 Hydraulic Repair can fix your hydraulic cylinders promptly and efficiently, so your operation doesn’t have to halt for too long. Call us today!